Understanding Marine-Grade Anodized Aluminum: The Premium Choice for Landscape Low-Voltage Lighting

In the world of landscape low-voltage lighting, the materials used play a crucial role in ensuring durability, longevity, and superior performance. One material that stands out for its exceptional qualities is marine-grade anodized aluminum. But what exactly is marine-grade anodized aluminum, how does it work, and why is it imperative for landscape lighting? Let’s dive into these questions to understand why this material makes our products the best on the market.

What is Marine-Grade Anodized Aluminum?

Marine-grade anodized aluminum is aluminum that has undergone an anodizing process to enhance its natural oxide layer, providing superior protection against corrosion and wear. The term "marine-grade" indicates that the aluminum alloy is specifically designed to withstand the harsh conditions of marine environments, including exposure to saltwater and coastal weather. These alloys often include elements such as magnesium and silicon, which significantly boost their corrosion resistance.

The Anodizing Process: How It Works

Anodizing is an electrochemical process that transforms the metal surface into a durable, corrosion-resistant, anodic oxide finish. Here’s a detailed breakdown of the process:

- Cleaning and Etching: The aluminum surface is first thoroughly cleaned to remove impurities. It is then etched to create a uniform surface.

- Anodizing: The cleaned aluminum is immersed in an electrolytic solution, usually sulfuric acid, and an electric current is passed through the solution. This causes oxygen ions to bond with the aluminum surface, forming an oxide layer.

- Sealing: The newly formed oxide layer is porous and is sealed to enhance its durability. This is often done by immersing the anodized aluminum in boiling water or a sealing solution to close the pores, preventing corrosion.

The Benefits of Marine Grade Anodized Aluminum in Landscape Lighting

- Corrosion Resistance: Marine-grade anodized aluminum is highly resistant to corrosion, making it ideal for outdoor use. It can withstand exposure to moisture, salt, and other environmental factors that typically cause deterioration in other metals.

- Durability: The anodizing process significantly increases the surface hardness of the aluminum, making it resistant to scratches, wear, and mechanical damage. This durability ensures that landscape lighting fixtures maintain their appearance and functionality over time.

- Lightweight: Aluminum is inherently lightweight, which makes it easier to install and handle during the setup of landscape lighting systems. Despite its light weight, anodized aluminum provides exceptional strength and stability.

- Thermal Conductivity: Aluminum has excellent thermal conductivity, which helps dissipate heat efficiently. This is particularly important in lighting applications where heat management is crucial to maintaining the longevity and performance of LED components.

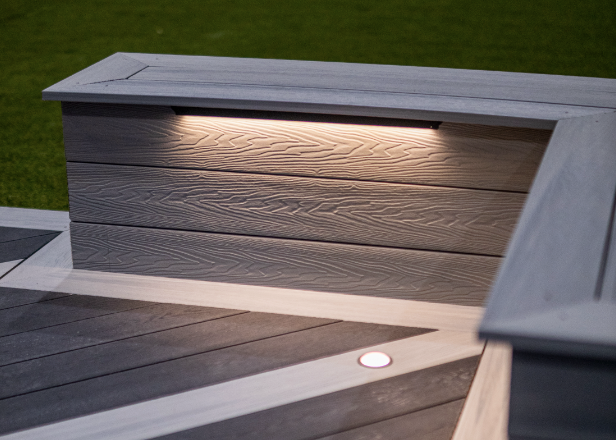

- Aesthetic Appeal: Anodized aluminum has a sleek, modern look that can enhance the visual appeal of landscape lighting fixtures. The anodizing process also allows for various color finishes, providing flexibility in design and aesthetics.

Why Marine-Grade Anodized Aluminum is Imperative in Landscape Low-Voltage Lighting

- Environmental Resilience: Landscape lighting fixtures are exposed to a wide range of environmental conditions, from rain and humidity to extreme temperatures. Marine-grade anodized aluminum's resilience to these elements ensures that the lighting system remains functional and visually appealing in any weather.

- Low Maintenance: The corrosion resistance and durability of anodized aluminum reduce the need for frequent maintenance and replacements. This makes it a cost-effective choice for long-term landscape lighting installations.

- Energy Efficiency: Low-voltage lighting systems are designed to be energy-efficient. The lightweight nature and thermal conductivity of anodized aluminum contribute to the overall efficiency of these systems by reducing the strain on the electrical components and enhancing heat dissipation.

- Enhanced Safety: Low-voltage lighting systems are safer to use around homes and gardens. The robustness and reliability of marine grade anodized aluminum further enhance the safety of these installations by preventing structural failures and electrical hazards.

Why Quality Makes Marine-Grade Anodized Aluminum Products the Best

- Longevity: High-quality marine-grade anodized aluminum products are built to last. They offer a significantly longer lifespan compared to other materials, providing better value for investment.

- Performance: Superior material properties ensure that the lighting fixtures perform consistently and reliably, delivering optimal lighting conditions for landscapes.

- Customer Satisfaction: Homeowners benefit from the reduced maintenance, enhanced durability, and aesthetic appeal of anodized aluminum fixtures, leading to higher satisfaction and positive reviews for you!

BOLD products are made of marine-grade anodized aluminum because it is an exceptional material for landscape low-voltage lighting due to its unmatched corrosion resistance, durability, lightweight nature, thermal conductivity, and aesthetic appeal. Its application in lighting fixtures not only ensures superior performance and longevity but also enhances the overall quality and reliability of the products, making them the best choice for outdoor lighting solutions.

If you have questions about this blog, or if you want to learn more about BOLD and our products, you can reach out to us at support@boldpros.com or give us a call at 1-833-472-9960.